CNC products material

CNC machining can offer high accuracy and multiple of material selections, when we see lots of CNC products, the material of which may be metal or plastic as below.

For designer, the variety of material can meet their original intention of design, such as excellent mechanical performance, graceful appearance, etc.

Sometimes the raw material can not completely realize the design, for example, the color, the limit of hardness, strength, corrosion resistance, etc. But we still find that the CNC products can avoid them by taking full advantage of the post-finish process, such as painting, anodizing, metal heat treating service, etc. The application of heat and other elements to metal parts could substantially elevate ductility, hardness, and other properties of the material.

Machining method of CNC products

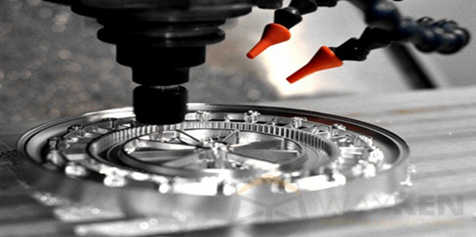

With the rapid development of technology, the CNC machining also get improvement not only from the equipment itself but also from the tool which make the CNC products have more complex structure. There are some machining methods are as bellows:

- CNC milling

- Flexible & universal:

CNC milling machine apply for a variety of different structural shape products, which can complete drilling, boring, reaming, milling plane, milling inclined plane, milling groove, milling surface (CAM), tapping thread, etc.

- Machine complex structure products:

Continuous 5-axis CNC milling allow for the movement of all five axes at the same time during machining operations.

- Maintain optimum cutting condition and improve cutting condition

As the tool moves toward the top or edge of the work piece, the cutting condition becomes worse. To maintain optimum cutting conditions here, a rotary table is required and continuous 5-axis CNC milling can do it.

- Effectively avoid tool interference

For the impeller, blade, integral disc and other parts used in aerospace field,

the three-axis CNC machining cannot meet the technological requirements due to

interference. However, 5-axis CNC machining tools can deal with these problems. At the same time, the five-axis machine tool can also use a shorter tool for processing, improve system rigidity, reduce the number of tools, to avoid the production of special tools.

- Reduce the number of clamping, a clamping complete five surface processing

- Improve machining quality and efficiency

- Shorten new product development cycle

For the aerospace, automotive and other fields of enterprises, some new products parts and molding shape is complex, precision is high. So the high flexible, high precision, high integrity and the ability to complete the processing of five-axis CNC machining center is a good way to solve the precision of the new product research and development in the process of complex parts processing and cycle problem, shorten the development cycle and improve the success rate of new products.

- CNC turning

Turning is a method of machining work piece by rotating the work piece relative to the tool on the lathe. Cutting energy for turning is provided primarily by the work piece, not by the tool. Turning suitable for processing rotary surface, most of the work piece with rotary surface can be processed by turning method, such as both cylindrical surface and conical surface are from the outside to inside , end face, groove, thread and rotary forming surface.

The lathe can be used not only for turning the work piece, but also for drilling, reaming, tapping and knurling with drills, reamers, taps and knurls

Industry of CNC products

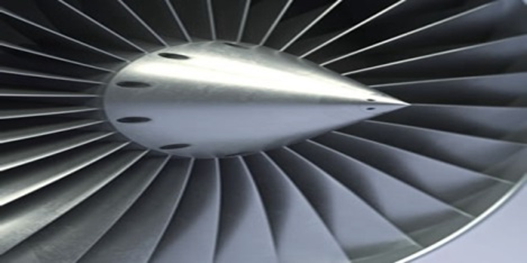

Aerospace

Machining has always been the main manufacturing means of aviation engine mechanism. Numerical control machining technology is mainly used in the manufacture of aero-engine for the machining of various complex components of compressor and turbine, such as casing, compressor disc, and turbine disc, turbine shaft, and compressor shaft. To assist with this manufacturing, the use of solvay materials can help with creating a lightweight machine that adds to sustainability using composite materials. Additionally, the aerospace industry also heavily relies on CNC machining for producing critical components with high precision and consistency. Aluminum, in particular, is a widely used material due to its excellent strength-to-weight ratio. The aluminum machine shop might use various alloys for producing spacecraft housings, radiators, and engine housings, ensuring reliability and performance in extreme conditions. Also, the metal is relatively inexpensive compared to other aerospace materials, making it a cost-effective choice for many components.

Automotive

Except the car shell, that is, the body is pressed out of the iron plate, most of metal and plastic parts belong to CNC products, CNC products are more widely used in automotive prototypes.

If this prototype is for functional testing, it has higher requirements on machining accuracy and quality.

For example, below car head lamps require not only good surface effect, but also the integrity of optical area.

The machined optical surface tolerance can reach +/-0.02mm. Then finishes can be achieved the best clarity and light transmittance through our specialized polishing process. Also, the final optical components are very accurate with excellent optical quality and free of any marks or scratches.

Robotics

When it comes to robot manufacturing, you have to mention: CNC precision parts processing.

Involve the robot prototype, will according to different attributes are divided into: robot, service robot, micro robot, the robot receptionists, community patrol robot,

bank service robots, robot education, teaching robot, buildin cleaning robot, robot, domestic robot competition, show the robot, special service robots, etc. Some robots are mainly made of plastic structure, whose shell is generally made of ABS material. If the shell of the robot is basically constructed by metal parts, the inside of the robot is also constructed by metal hardware parts. Generally, the metal is made of aluminum alloy 6061, and 7075 aluminum parts can be used as the robot hand plate.

Medical device

Da Vinci surgical robot is popular all over the world. More and more medical robotics are born at this moment. This kind of CNC products require much high accuracy because they are used in the surgical operation which significantly affect the life.

Conclusion

CNC products can be seen everywhere, they may be made from different materials, by different CNC machining methods, or be applied for different industries. But they all start from the excellent design of designer and realize by the CNC machine manufacture, and then make our life more colourful. Take a look at this CNC machine shop for more information and services.